Kosaka Laboratory Ltd.

Kosaka - Lubricating Oil Pump (Centrifugal Pump)

- Suitable for transferring large capacity lubricating oil, sea water and chemical liquid (Submerged Cargo Pump) for chemical tanker, ship and power plant.

- -Flow rate: Up to 2000m3/h

- -Head: Max 10MPa

(Centrifugal Pump)

(Centrifugal Pump)

[Full length 12m]

Item |

Horizontal Multi Impeller Pump |

Horizontal Multi Suction Single Impeller Pump |

Horizontal Single Impeller Pump |

|

Model |

Barrel Type |

Balance Disc Type |

Horizontal Separate Type |

Center Support Type |

CHM-B |

CHM |

CHD |

CHP |

|

Flow rate [m3/h] |

4-600 m3/h |

4-600 m3/h |

200-2000 m3/h |

4-300 m3/h |

Head [m] |

100-1000 m |

100-1000 m |

6-200 m |

6-130 m |

Flange Diameter [mm] |

40-300 mm |

40-300 mm |

200-500 mm |

40-250 mm |

Applications |

Burning, Fuel Oil, Waste Oil, Water supply to Boiler |

Burning, Fuel Oil, Waste Oil, Water supply to Boiler |

Fuel Oil |

Fuel Oil, Waste Oil, |

Item |

Horizontal Single Suction, Single Impeller Pump |

Vertical Multi Impeller Pump |

Vertical Multi Impeller Pump |

|

Model |

CHS |

CVB |

CSS |

CSKT |

Flow rate [m3/h] |

4-300 m3/h |

10-300 m3/h |

15-300 m3/h |

15-300 m3/h |

Head [m] |

6-130 m |

100-1000 m |

100-150 m |

10-250 m |

Flange Diameter [mm] |

40-250 mm |

40-300 mm |

50-250 mm |

50-250 mm |

Applications |

Fuel Oil, Waste Oil, |

Fuel Oil, Waste Oil |

Burning, Fuel Oil, |

Lubrication Oil |

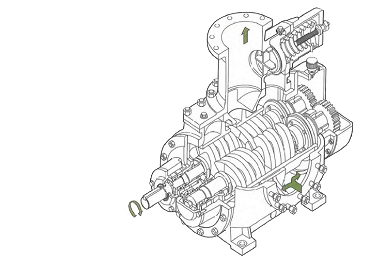

Kosaka - Twin Screw Pump

- For all liquids from low to high viscosities and corrosive.

- Self Priming

- Non pulsating flow

- High suction

- Low noise

- Compact and space saving design

- Less wear thanks to non contact between screws

Applications in Thermal Power Plants

- Heavy & Crude Oil Transfer Pump

- Coal Oil Mixture (COM) & Coal Water Mixture (CWM) Transfer Pump

- Orimulsion Trans Pump

- Heavy & Crude Oil Burning Pump

- COM & CWP Burning Pump

- Orimulsion Burning Pump

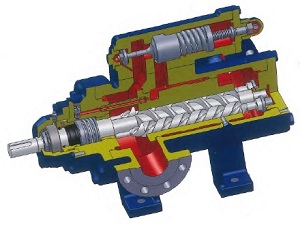

Kosaka - Three Spindle Screw Pump

- Simple construction

Rotating elements are only one power rotor and two idler motors. Construction is simple.

- Trouble free operation

Reasonable construction results trouble free running and easy handling in the field.

- Low noise

As rotating elements are only three rotors and comparatively small, and also idler rotors are rotated by liquid pressure, natural, smooth, low noise running is ensured even at high revolution and pressure.

- Low pulsation and agitation

Liquid enclosed into chambers sealed by rotors and sleeves is transferred continuously from suction to discharge without pulsation and agitation.

- Long service type

As pressure acted to rotating elements is balanced completely, rotors and sleeves are not disturbed by obstructed pressure, and also, as idler rotor are revolved by liquid pressure, and lubricated by liquid pumped, there are no direct touches among rotor and sleeve. Therefore wear is kept extremely low.

- High operating efficiency

There is no direct transmission of power to idler rotors and internal pressure acted to rotating elements is balances, so friction loss is very small. And also, internal leakage loss is kept low with precise machining of rotating elements.

- High suction lift

As liquid is transferred to thrust direction continuously without agitation and also sealed chambers works as in finit piston, high suction lift is ensured easily without cavitation.

- Small starting torque

As inertia of rotating elements is small, starting torque is small.

- Compact and large capacity

Since high speed driving is possible for a pump, it is compact also at large scale.

[Lubricating Oil Pump]

[Fuel Oil Burning Pump]

Spare and Maintenance Parts

- We offer spare and maintenance parts for almost all pumps. Click the below photo to check the spare parts.

- Available spare parts (examples)

ADJUSTING RING, ADJUSTING SCREW, ANNULAR NUT, BALANCE PISTON, BALL BEARING, BEARING NUT, BEARING SEAT, BEARING WASHER, COUPLING RUBBER, FELT RING, GASKET, HEX HAXL NUT, IMPELLER NUT, IMPELLER WASHER, KEY, MECHANICAL SEAL, NECK BUSH, OIL SEAL, O-RING, SET SCREW, SHEET GASKET, SLEEVE, SNAP RING, SPRING PIN, SPRING SHEET, SPRING WASHER, STRAINER, THROAT BUSH, THRUST SEAT, WEARING RING, etc.