Products > Product for LiB Industry

Nagano Automation

Devices for lithium-ion batteries

Electrode cutting machine for lithium-ion secondary batteries etc.

Machine to cut positive electrode or negative electrode of lithium-ion batteries etc. from original roll to batteries size.

Laminating machine for lithium-ion secondary batteries etc.

Machine to pile up positive electrode or negative electrode of lithium-ion batteries and separator in sequence with high accuracy and high speed.

Jerry-roll (JR) insertion machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert jerry-roll and bottom insulator to external can of cylindrical lithium-ion batteries etc.

Injection machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to inject electrolyte into cell in the manufacturing process of items such as lithium-ion batteries, etc. Developed to shorten the impregnation time by application of pressure in addition to vacuum immersion.

Sealing port laser-welding machine for cylindrical (18650) lithium-ion secondary batteries etc.

Machine to insert sealing port and positive electrode tab to external can after welding by laser in the manufacturing process of items such as lithium-ion batteries, etc

Electrolytic injection machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to inject electrolyte into cell in manufacturing process such as lithium-ion batteries etc. This machine requires manual operation and is intended for small-quantity production.

Degassing and sealing machine for lithium-ion secondary batteries etc. for small-quantity production

Machine to discharge gas produced at the first charging in manufacturing process of lithium-ion batteries etc. from batteries cell and to reseal.

Noritake

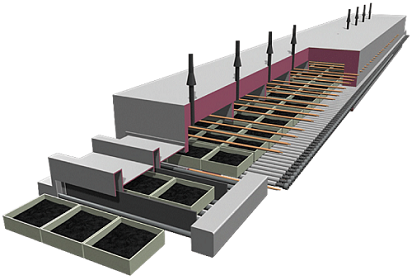

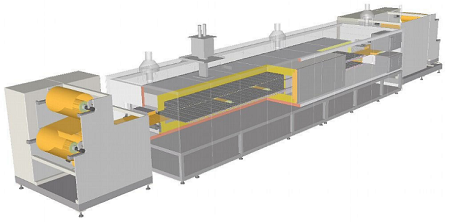

Roller Hearth Kiln

Roller Hearth Kiln (RHK) is a continuous firing kiln which

transports products using ceramic rollers.

RHK provides outstanding temperature uniformity,

cleanliness and heat efficiency.

We offer in a wide range of scale; from small lab

types to mass-production systems.

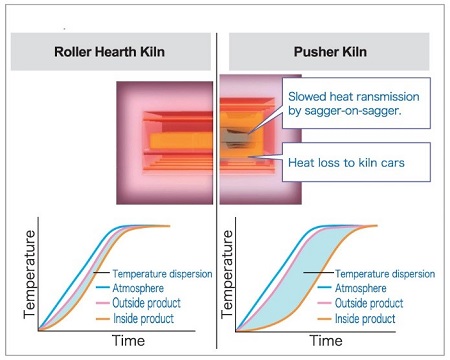

Fast and Uniform Firing

Placing green materials without stacking realizes homogeneous

and high speed firing.

● RHK's roller transportation method makes radiant heating from all directions possible and narrows temperature deviation to ±2℃.

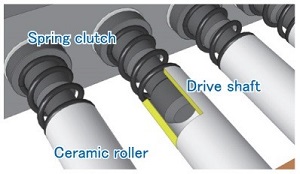

● Conveyor rollers are driven by Spring Drive. This allows for high speed transfer without meandering.

< Roller Drive >● RHK's roller transportation method makes radiant heating from all directions possible and narrows temperature deviation to ±2℃.

● Conveyor rollers are driven by Spring Drive. This allows for high speed transfer without meandering.

< Comparison of cross section >

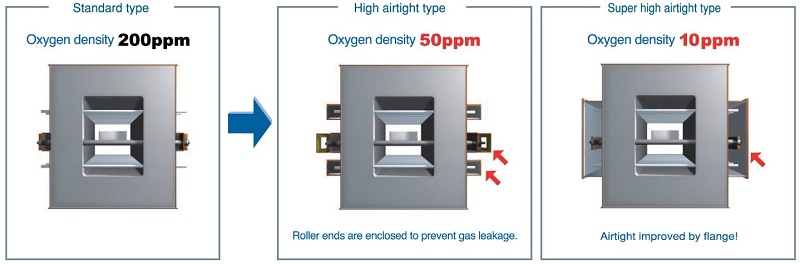

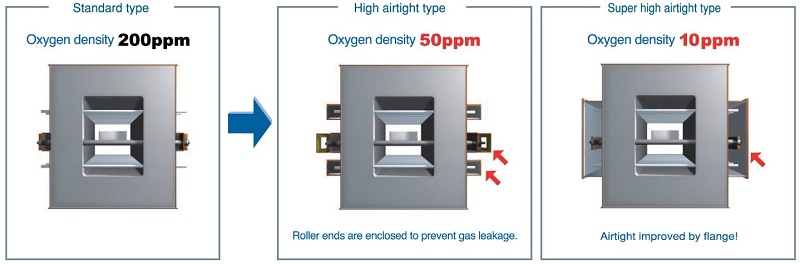

High Gas Tightness

Sealing options are available for efficient firing environment with special gases.

< Comparison of airtight grade >

< Comparison of airtight grade >

Vacuum Heating System

●Labor Saving

Processes without human operators prevent contamination of materials and dry room.

●Safety Improvement

Reduces safety risks by replacing operators in heavy-lifting/transporting tasks.

●Processes Integration

Establishes automated transfer line with preceding and subsequent processes.

Optional: Upward communication, Product traceability with barcode system

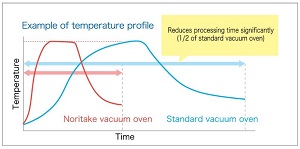

● Shorter Processing Time

Raising the temperature and the heat transfer medium in cooling (N2, CDA, Ar) use.

To shorten the processing time by its own circulation mechanism.

● Uniform Heating

Homogeneous heating between the inside and outside of materials improves the product quality.

● Establishing Optimum Recipes

Flexible control system for developing temperature settings.

Operating temperature:R.T.~250℃

Temperature precision:±5℃

Atmosphere:N2、CDA、Ar

Vacuum level:10Pa(7.5×10-2 Torr)

Heat source:Electricity

※Optional: Doors on both side, barcode management

Temperature precision:±5℃

Atmosphere:N2、CDA、Ar

Vacuum level:10Pa(7.5×10-2 Torr)

Heat source:Electricity

※Optional: Doors on both side, barcode management

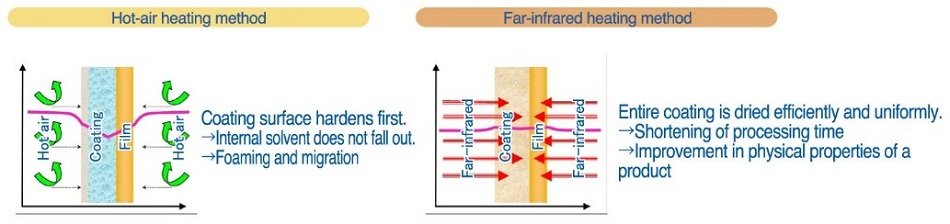

Far-infrared Heating System

Roll to Roll Far-infrared Heating Furnace

Infiltration of far-infrared ray reduces treating time significantly by heating inside and outside of film simultaneously.

●Cross section model on heat transferring (early stages of heating)

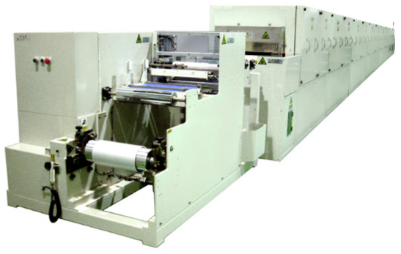

Roll to Roll Far-infrared Film Anneal Furnace for Optical film

Operating temperature : R.T.~450℃

Temperature precision : ±3℃

Atmosphere : Air、N2(Option)

Clean level : Class 1000

Film width : 500~1700 mm

Conveyance tension : 0 N

Temperature precision : ±3℃

Atmosphere : Air、N2(Option)

Clean level : Class 1000

Film width : 500~1700 mm

Conveyance tension : 0 N

● Uniform Heating

Heater zone arrangement of our far infrared heaters for wide-width film provides a high-accuracy temperature profile.

● Roll to Roll conveyance system for Optical film

We suggest our conveyance system to reduce load on conveying in heating and not to cause distortion and damage caused by conveyance on products.

Applications

· ITO film crystallization anneal process

· Anneal process for various types of function membrane film

· Individual annealing treatment process for Optical film (PI, PEN, PET, PMMA etc.)

Heater zone arrangement of our far infrared heaters for wide-width film provides a high-accuracy temperature profile.

● Roll to Roll conveyance system for Optical film

We suggest our conveyance system to reduce load on conveying in heating and not to cause distortion and damage caused by conveyance on products.

Applications

· ITO film crystallization anneal process

· Anneal process for various types of function membrane film

· Individual annealing treatment process for Optical film (PI, PEN, PET, PMMA etc.)